Since its existence, human being has built shelters to protect itself from external threats. These shelter systems are masonry construction systems that have existed for many years and are still in use today. All historical monuments and monumental constructions that have survived for centuries in our country have been built with this system.

Earthquakes are one of the most important natural events that have the potential to influence human and living life on earth. As is known, our country lies on one of the world's most active seismic zones. As well as we had many destructive earthquakes in our past, it is a fact that and we will suffer great loss of life and property with earthquakes that will occur frequently in the future. The shear strength of masonry structures is very low under earthquake loads.

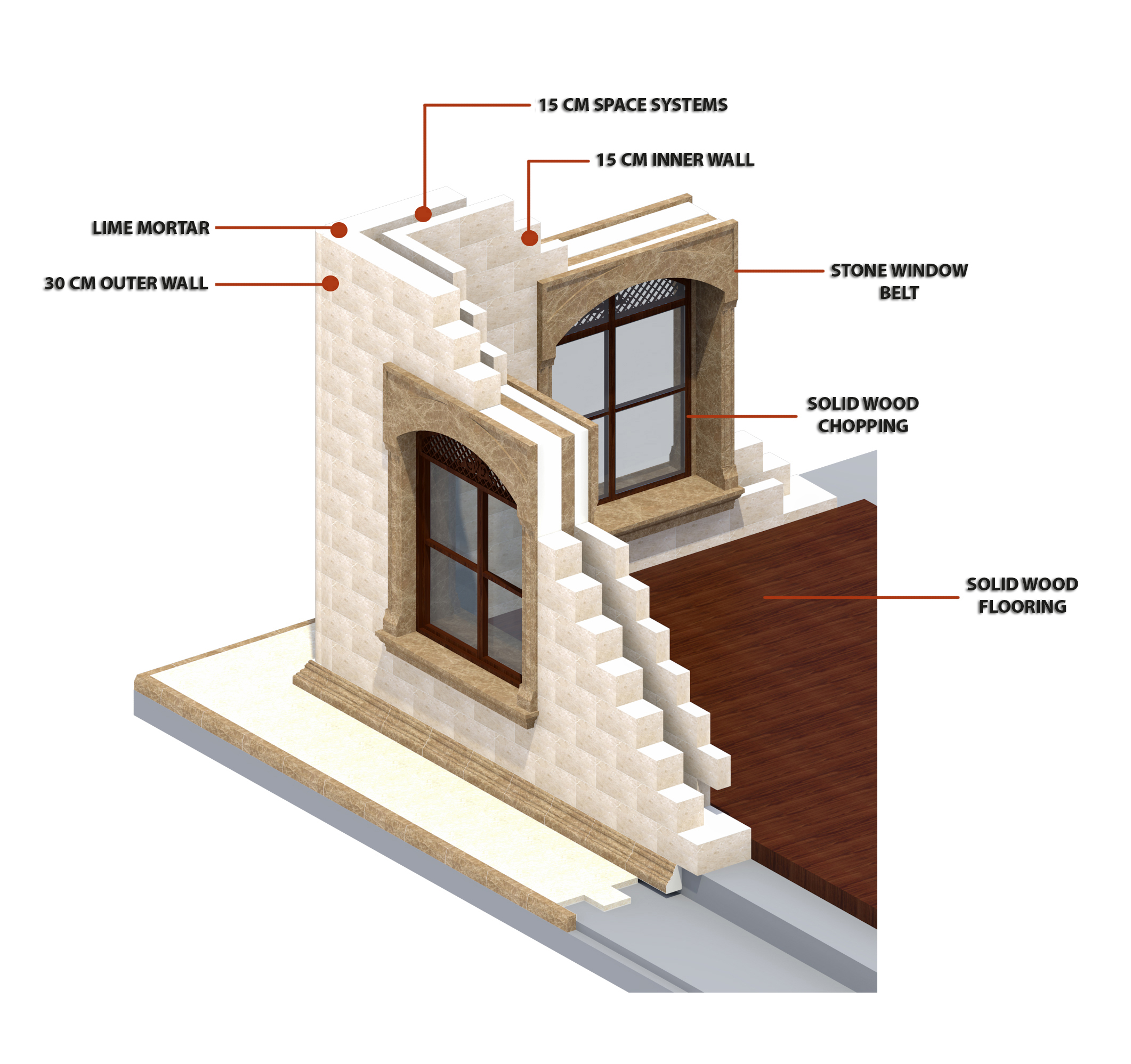

Historically, multi-layered walls (Layers, respectively: Wall, rubble, wall) have been preferred in order to increase the shear and compressive strength of masonry stone buildings which are a sort of these structures. The main disadvantage of this preferred wall system is the increase in wall thickness, which results in an increase in earthquake load due to the increase in building weight. Our building to be applied is designed to reduce the earthquake load which will affect the building load and consequently the building by removing the existing rubble layer in the multi-layered walls and to connect the two walls to each other with clamps and dowels. As a result, a very durable and reliable building system has emerged.

Limra will be used in our building as natural cutting stone in the carrier system in accordance with the architectural project. The mechanical and physical properties of the stone have been extensively studied and the stone has more compressive strength than the strongest concrete alone. Single layered and double layered masonry walls were studied together and their behaviors under earthquake loads were examined experimentally and theoretically. In the double layer walls, the layers should be connected to each other by rectangular clamps, leaving a gap of 15 cm between the first layer and the second layer, leaving a gap between the two walls, the walls being connected to each other by clamps and operated as a single wall. This system makes our building even stronger.

The flooring system of our building has been planned as Composite flooring with concrete using with steel profiles. The connection of the flooring with the walls is realized with steel anchors at the end of the wall. This will reduce the weight of the building and thus reduce the earthquake loads from the building. In addition, the space which will occur between the two walls will be used for insulation and electrical installation. This will prevent image pollution that will form outside the wall and will even save the place to cover it outdoors. When insulation is thought to be an indispensable innovation in today's technology, this gap will be used for insulation in masonry structures and it will be a novelty in terms of isolation of masonry cut stone buildings. The masonry building which will be warm in winter and cool in summer is of a natural structure to stay for centuries which is longed for.